Welcome to this deep-dive edition. Every two weeks, I go down the rabbit hole on interesting topics that have shaped our world through the lens of technology. We also release a weekly newsletter (The Weekly Signal) showcasing the latest curated signals that caught our attention.

Before we get started, here are just a few terms and nuances to get yourself acquainted with some of the semiconductor linguo you’ll encounter in this deep dive.

The terms “fab” and “foundry” are sometimes used interchangeably, but that’s technically incorrect. Knowing the difference is important so you can better understand the key differences throughout this deep dive:

Fabs (short for “fabrication”) are facilities in which semiconductor products are manufactured.

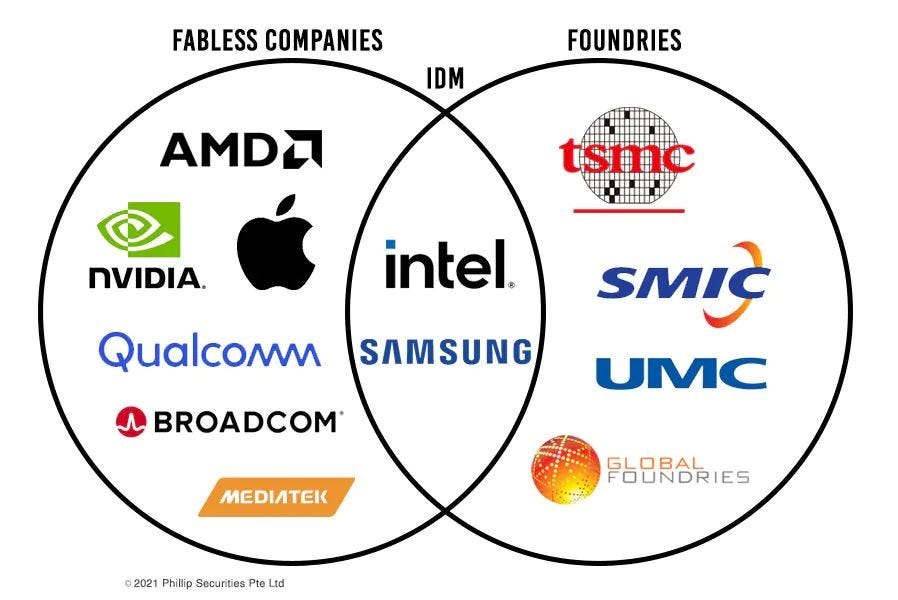

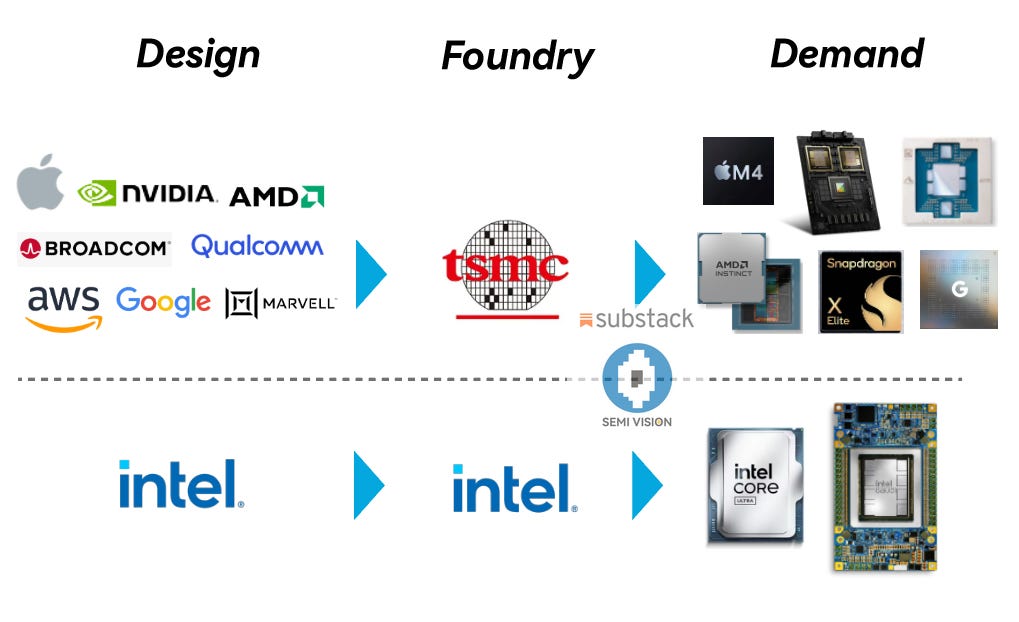

Fabless companies focus on designing chips. They partner with other companies (foundries) for the manufacturing phase. This is Apple, AMD, or Nvidia.

Foundries are companies that manufacture semiconductor products as a service. They do not design chips. This is TSMC.

Integrated device manufacturers (IDMs) design and manufacture their own chips in their own fabs. This is Intel or Samsung.

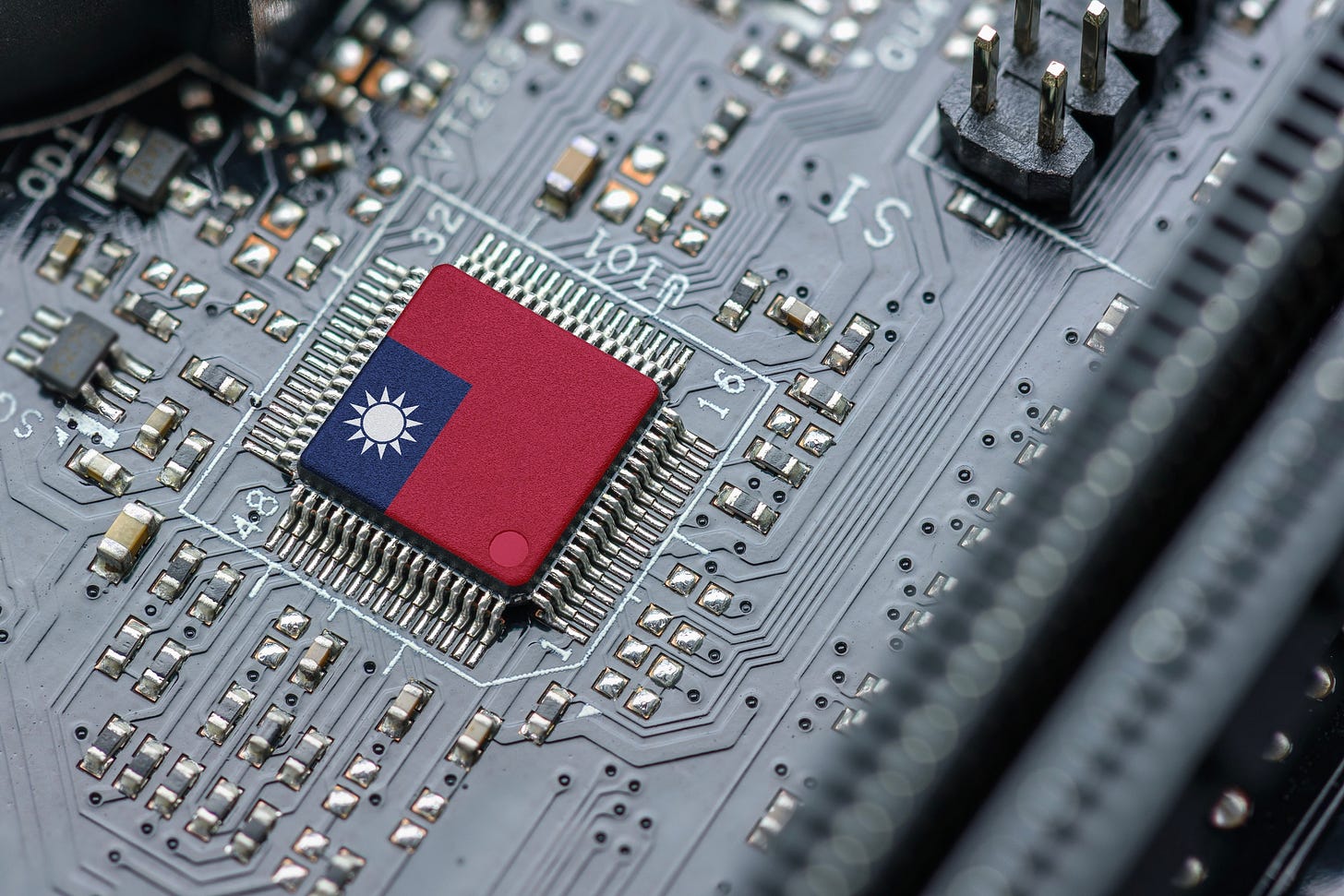

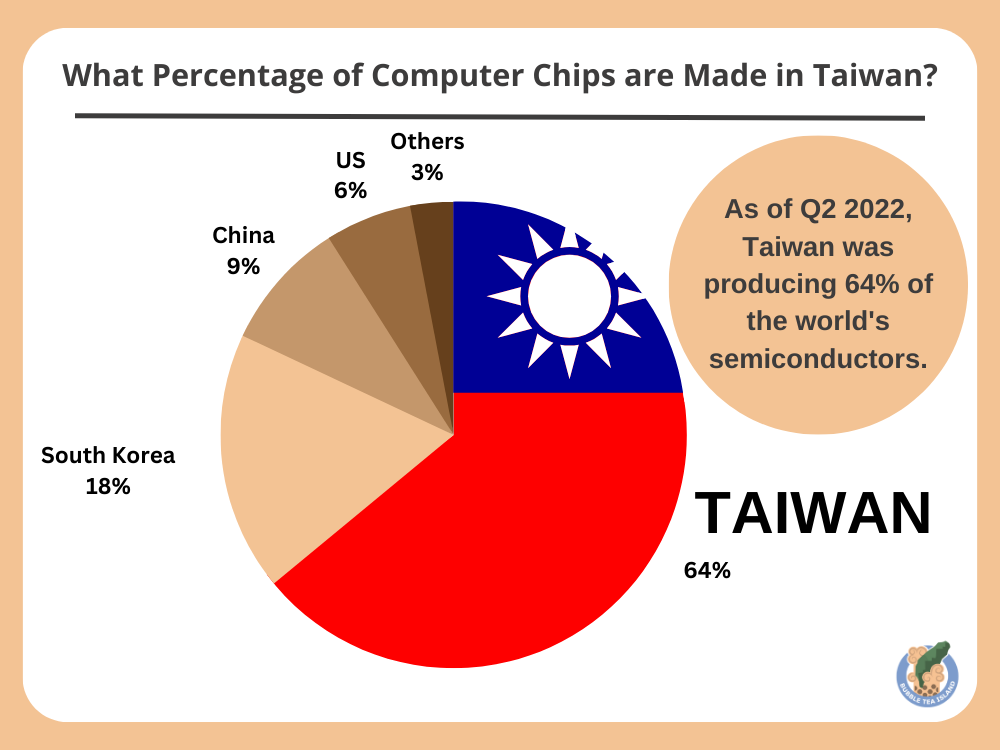

It’s fair to say that there is only one country on Earth that can declare itself the semiconductor capital of the world. It’s not the United States, it’s not Japan, and it’s not China.

Did you know that around 60% of the world’s microchips and 90% of the most advanced ones come from Taiwan?

This means that the computer or phone you’re reading this deep dive on right now (subscribe!) is powered by semiconductor chips sourced from this very region. And it’s not just laptops and phones, it’s anything that has a computer inside of it — the smart TV you’re binge watching Netflix on, your Google Home, the car you drive…basically any electronic device that you own contains at least one component that was manufactured in Taiwan.

Now, while there are many semiconductor companies in Taiwan, there is only one company in particular that has been put under the global spotlight—that’s Taiwan Semiconductor Manufacturing Company, or better known as TSMC

To put this company into perspective, TSMC alone commands the lion’s share, holding 61.7% of the global foundry market in Q1 2024, climbing to 64% by Q3 2024. This growth, fueled by the AI boom and post-ChatGPT era, reflects a surging demand for these advanced AI chips.

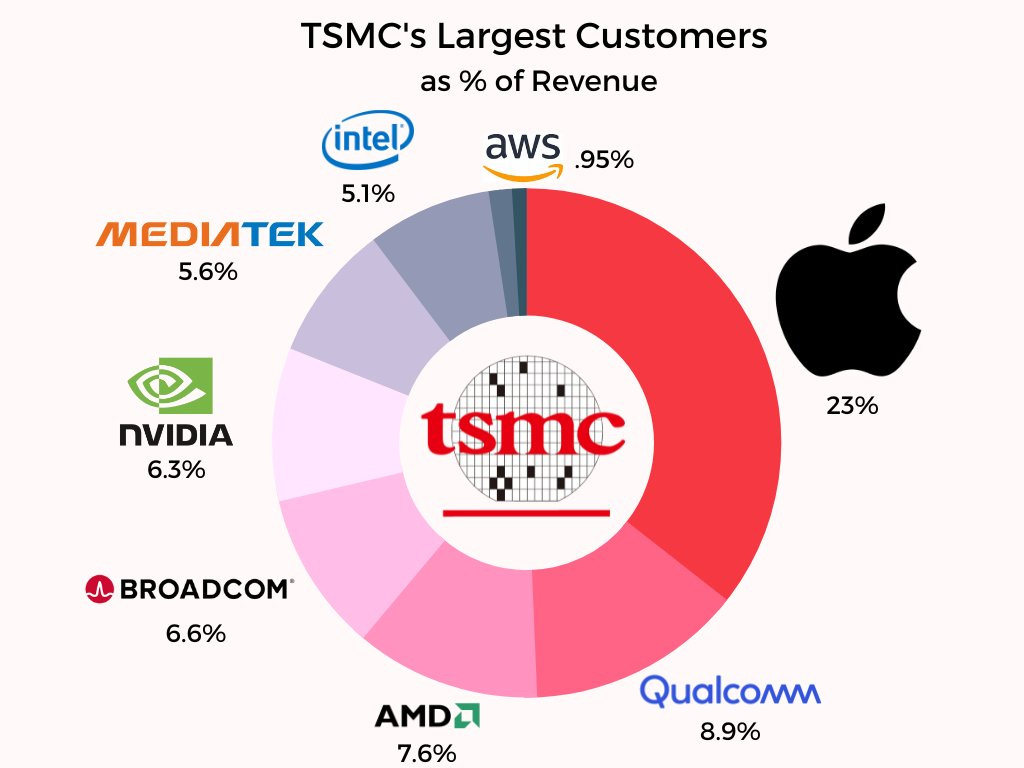

TSMC works with some of the biggest clients in the world, including Apple, Nvidia, AMD, and Qualcomm. And all of them rely on the chip manufacturer to produce chips at scales and precision that others can’t match. For example, Apple’s A-series processor and Nvidia’s AI accelerator chips depend heavily on TSMC’s nanometer technology, which not only includes their state-of-the-art equipment but also their unique foundry model.

To understand TSMC’s rise, we have to understand its core business strategy, which has been executed relentlessly for the past 30+ years. I’m referring to their foundry model, in which they manufacture chips designed by others, unlike Integrated Device Manufacturers (IDMs) like Intel or Samsung, who design and produce their own (we’ll touch on this later). It was this specialization, pioneered by TSMC’s founder Morris Chang, that allowed the company to scale efficiently, avoid conflicts with clients, and invest heavily in technology innovation. By 2023, TSMC’s market cap ranked it among the world’s top 10 companies, alongside giants like Meta and Berkshire Hathaway, with a valuation exceeding $500 billion.

But let’s go a bit deeper and figure out the backstory of TSMC and how it made Taiwan into a semiconductor powerhouse.

Taiwan’s Path to Semiconductor Glory

Taiwan hasn’t always been a dominant innovator like it is today.

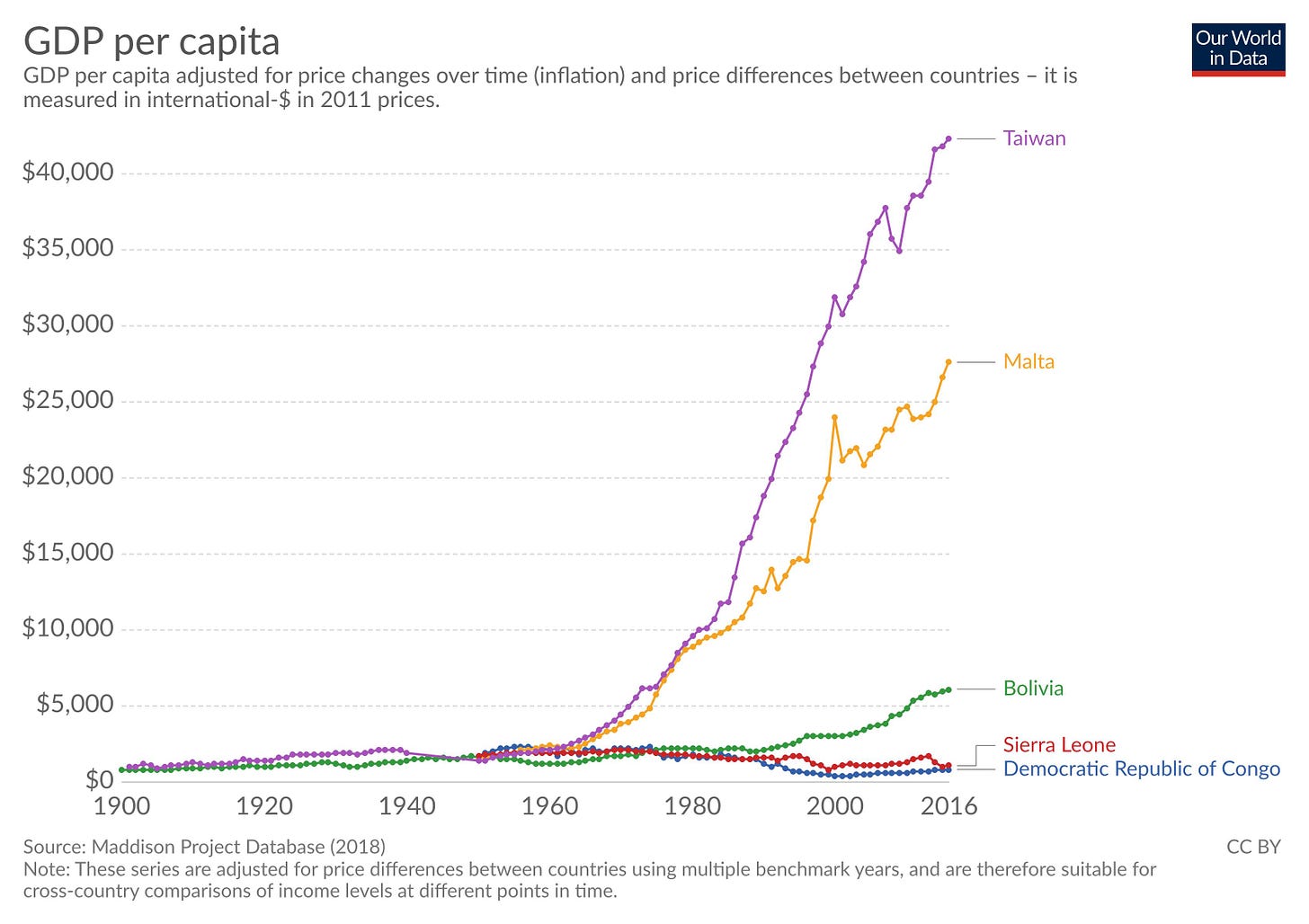

In the mid-20th century, the country was quite poor and agrarian. Its economy was rooted in sugar exports, with its GDP per capita similar to that of sub-Saharan African nations. It also went through phases of colonization by the Dutch and the Japanese.

But it all turned after the Chinese Civil War in 1949, when the Nationalist Government (KMT) fled to Taiwan with over 2 million refugees, which was aided by the United States. Taiwan went through a huge amount of reform that boosted agricultural output by 150% from 1950 to 1960, freeing resources for industrialization.

The graph below speaks volumes about the country’s sheer growth from the 1950s:

It turns out that the KMT was quite authoritarian, with four decades of martial law, which had shaped early economic policy during the 1950s. During this time, the US basically bankrolled Taiwan, contributing up to 40% of foreign investment into the country, funding infrastructure, and imposing import restrictions to nurture local industries. By the 1960s, Taiwan had shifted to export-led growth, becoming a hub for low-cost manufacturing — toys, textiles, and electronics.

This was a pivotal moment because it was when companies like IBM began outsourcing assembly, laying the groundwork for the region’s tech expertise.

The real pivot came in the 1970s after being battle-hardened by the oil crisis’s economic shocks. This is where Taiwan’s government launched the Industrial Technology Research Institute (ITRI) in 1973, with a mission to build a semiconductor industry. It contained the brains trust of tech, enlisting some of the country’s best electrical engineers and scientists to help build and promote it.

It was here that the RCA project was born, where in 1976, the Radio Corporation of America initiated a knowledge transfer of Integrated Circuit (IC) technology to Taiwan — this was all the knowledge and innovation behind the semiconductor. ITRI’s success birthed the United Microelectronics Corporation (UMC) in 1980, now a top-five foundry, which set the stage for TSMC.

Mr. Chang

Enter Morris Chang. A figure I find pretty pivotal to all of this.

Born in China, Chang moved to the US at eighteen, studying at MIT and Stanford before joining Texas Instruments (TI) in 1958. At TI, he essentially honed chip production, reportedly making dozens of transistors hourly, which was pretty damn fast back then. Chang eventually rose to one of the top folks at TI, and he was in line for the top role (CEO), but was unfortunately overlooked for the job. I

It was when Chang migrated back to Taiwan that he would join the ITRI in 1985, and then founded TSMC in 1987 with government backing via their National Development Fund, with a 48% stake. Philips had a 28% stake.

Side note: It’s funny how life works out. One door closes and another one opens.

The unique thing about TSMC was that Chang’s vision for his company was very clear right from the beginning — a pure-play foundry, manufacturing chips for design houses unable to afford their own fabs, which would cost billions to build.

This vision set the core foundation for TSMC, because it meant they were bold right from the early days. TSMC knew this as they clearly wanted to become a dominant player in the semiconductor space against UMC locally, but also against other global competitors.

They priced chips at a loss to gain market share as quickly as possible, making a huge bet that rising fab costs would push Silicon Valley companies to outsource. Eventually, that gamble paid off. By the 1990s, TSMC became a trusted partner for fabless firms like Nvidia, cementing Taiwan’s role in the global supply chain.

To provide even more perspective, the visual of the Venn diagram above clearly shows the differences between fabless companies, foundries, and IDMs. By having a foundry model, TSMC was able to focus all its efforts on the manufacturing side of semiconductors and less on the design.

Shortly, we will see why the IDM model didn’t work.

The Silicon Shield

TSMC’s dominance isn’t just economic. It’s also become geopolitical.

Over the years, Taiwan has developed quite a reputation for itself not only on the technology side, but also on the geopolitical front in its dynamic with Western powers like the US and that with China.

Have you ever heard of the term “Silicon Shield”?

Over the years, Taiwan has received this name because of the interplay with the United States and China.

Taiwan’s “Silicon Shield” is the idea that it’s current chip supremacy deters Chinese aggression, as disrupting TSMC and others, which would result in the crippling of global tech. China claims Taiwan as its territory, and tensions simmer, yet the interesting thing is that TSMC supplies both US firms (Apple, Nvidia) as well as Chinese ones, with China accounting for a huge share via the “triangle trade”.

It gets even more interesting on the supply chain, because while Taiwan does the manufacturing, it then outsources the assembly to China, which then exports the final goods back to the US!

This puts Taiwan in a very unique position.

Both superpowers see their massive reliance on Taiwan as a huge vulnerability.

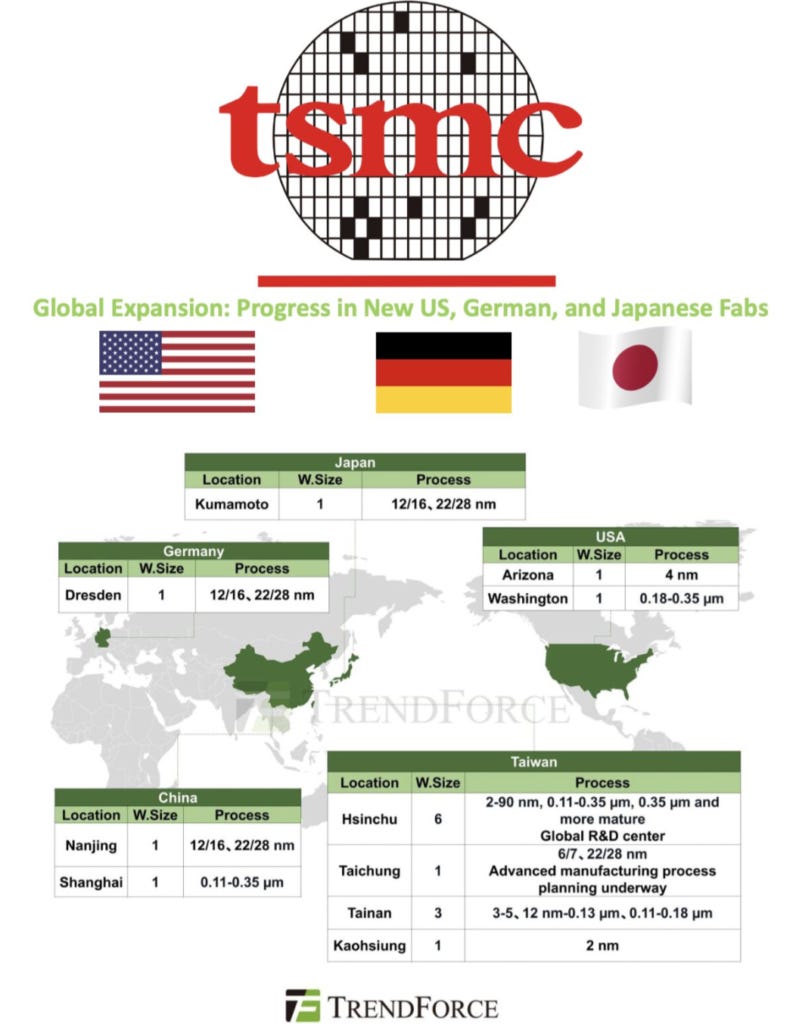

What this means is that both sides are now investing heavily in their home soil to reduce their dependency on Taiwan. For example, we’re already seeing China’s own foundry, SMIC (Semiconductor Manufacturing International Corporation), the world’s third-largest, invest heavily in R&D, enabling it to reach 7nm in 2022 and is eyeing 5nm in the near future. Meanwhile, the US is also investing via the CHIPS Act, which awarded TSMC $6.6 billion for a $165 billion Arizona campus. The hope is that by 2028, Arizona’s fabs will produce 5nm chips, reducing US dependence on Taiwan.

Outside of the US, TSMC is already building out its global footprint across Germany and Japan. If you look carefully at the image below, you can see that different fabs have different process capabilities. The fabs in China have been designed to produce chips at the “µm” (micrometer) range and larger nm sizing, while those outside China have access to “nm” (nanometer) technology, which is the current and future generation of chip manufacturing — the smaller the better.

It looks like TSMC is playing their cards close to their chest in ensuring that China doesn’t have access to the latest and greatest tech advancements.

But the idea that being self-sufficient will solve this dependency issue is still a myth. The reality is that semiconductors rely on a global supply chain. Silicon comes in from Japan, chemicals from Germany, and equipment from the Netherlands (ASML).

So if the Silicon Shield weakens as the US and China build out domestic capacity, Taiwan’s strategic leverage could erode.

ASML and nanometer tech

Let’s quickly talk about ASML because this company doesn’t get a lot of media attention, as it should.

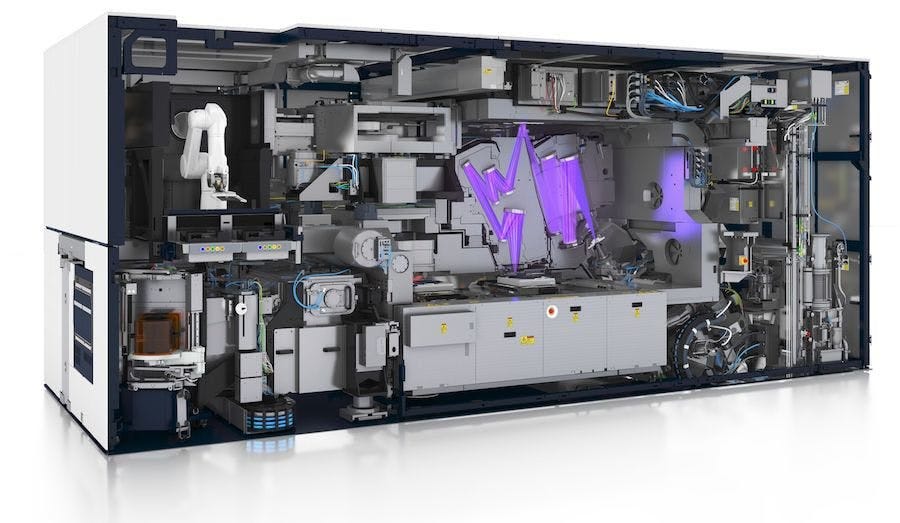

ASML, a Dutch company, is responsible for building some of the most advanced semiconductor machines on the planet. They make photolithography machines essential for chip production, especially Extreme Ultraviolet (EUV) lithography machines needed for advanced semiconductors. These machines etch tiny patterns on silicon wafers, enabling chips used in smartphones, AI, and more.

I highly recommend you watch the video below to give you a better sense of how EUV works.

EUV lithography allows for incredibly small features, down to 8nm, compared to a human hair’s 80,000nm. This means faster, smaller, and more efficient chips.

The crazy thing about ASML is that it holds a near-monopoly in EUV technology, with 67% of lithography sales and no significant rivals today. Earlier competitors like Ultratech, Canon, and Nikon focused on non-EUV lithography, but none match ASML’s EUV capabilities. This monopoly makes ASML a powerful gatekeeper.

Samsung, Intel, and the IDM Model

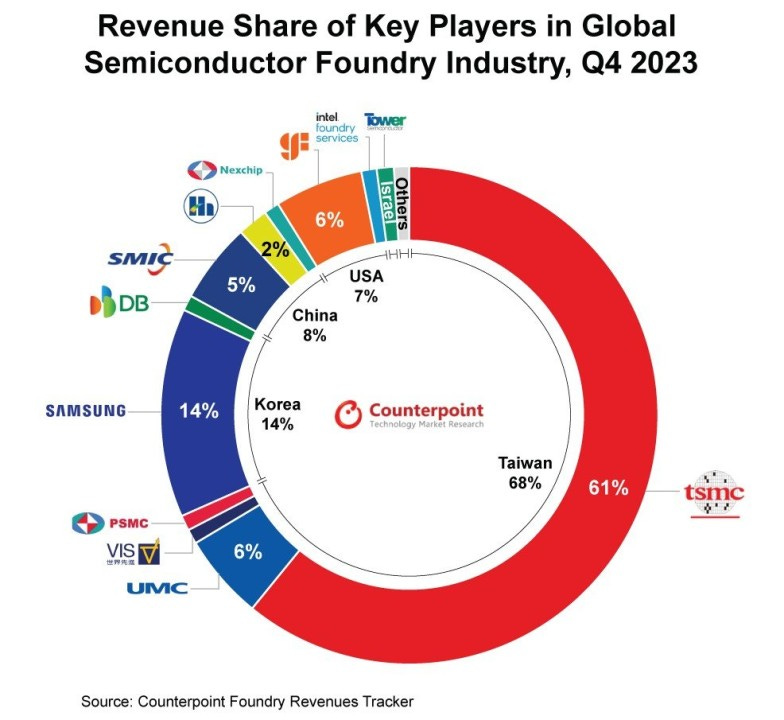

Remember earlier when I mentioned how giants like Samsung and Intel decided to pursue their IDM path? Well, it turns out that was probably the wrong move.

Why? You see, TSMC’s pure-play foundry model gives it a strategic edge over IDMs, whose dual role as both a designer and manufacturer has cost them.

Back in the 2000s, Samsung actually made Apple’s A-series chips up until 2010, but its Galaxy phones, using in-house designed chips, sparked IP disputes because it was believed Samsung had used proprietary Apple knowledge to do so. Apple sued, winning $548 million, and then switched to TSMC, which now supplies all iPhone processors. Samsung’s foundry share is now only 11%, a seventh of TSMC’s, as their clients fear conflicts.

Similarly, Intel also stumbled. Its refusal to manufacture Apple’s chips in 2010, prioritizing its own designs, pushed Apple to TSMC, a decision Intel later regretted as its foundry had fallen behind.

The pie chart below speaks for itself.

You can also see the key differences between TSMC and Intel below. One of them works with multiple unique customers, helps them manufacture the designs, and produces a variety of high-performance chips, while the other does both the design and manufacturing, leading to isolation.

But in breaking news (April 4, 2025): TSMC is now in talks with Intel to help them run their foundry business through a joint venture. Here’s a snippet to give you an idea of what the deal could look like and why.

Intel (INTC, Financial) is getting a lifeline—and it's coming from an unlikely partner. Taiwan Semiconductor Manufacturing Company (TSM, Financial) is stepping in to co-run Intel's chip factories through a new joint venture, with TSMC taking a 20% stake, according to insiders cited by The Information. The deal, still in its early stages, follows months of pressure from the White House to get the two rivals on the same page. If it moves forward, this could mark a major turning point not just for Intel, but for the U.S. semiconductor industry's push to regain relevance in the global chip race.

Intel has been in deep trouble. It lost $18.8 billion in 2024—its first annual loss since 1986—and fell woefully behind in the AI chip boom. While competitors sprinted ahead, Intel kept sinking billions into its foundry business, but couldn't match the speed or service levels of TSMC. Former execs pointed to failed tests, missed deadlines, and unhappy customers. The company's new CEO, Lip-Bu Tan, a seasoned semiconductor veteran, now has the near-impossible task of engineering a comeback—and this deal with TSMC might be his boldest move yet.

TSMC isn't just doing Intel a favor—it's doubling down on its U.S. expansion. The Taiwanese giant recently unveiled a $100 billion plan to build five new fabs in the U.S., and this Intel JV would give it even deeper roots. For investors, this partnership could rewrite the narrative. After losing 60% of its value last year, Intel shares are up only 3% in 2025. If this deal locks in, and if Intel can finally start shipping on time with TSMC at the helm, we may be looking at the start of one of the more surprising tech turnarounds of the decade.

The Future

I think it’s fair to say that what TSMC has built for itself is nothing short of incredible for both the semiconductor industry and for Taiwan. It’s fair to say the country isn’t as resource-rich as many others, like the Middle East or Australia, but through sheer innovation, it’s been able to build itself into one of the most advanced countries in the world.

Looking forward, I still see TSMC continuing to remain at the center of the global semiconductor industry. But, in terms of what happens next, the world is going to look very different in the next couple of years. There is a strong push to offshore manufacturing outside the country. The increasing rivalry between China and the US means tensions are high, and efforts to set up factories outside of the region stay true to how forward-thinking TSMC is in terms of its survivability over the next decade.

And I think with everything happening right now with AI and geopolitically, that there will be other players who come through the ranks to not only compete with TSMC, but ensure there is a thriving ecosystem of competition and alternatives for the industry to pick and choose from.

🙏🏼 Connect with Me

Are you new to the newsletter? Subscribe Here

Learn more about me on my website

Check out my YouTube channel (and subscribe!)

If you’re a founder, apply here (Metagrove Ventures) for startup funding or contact me directly at barry@metagrove.vc

If you think this could be helpful and informative to others, please share it :)

Thanks for reading.

Barry.